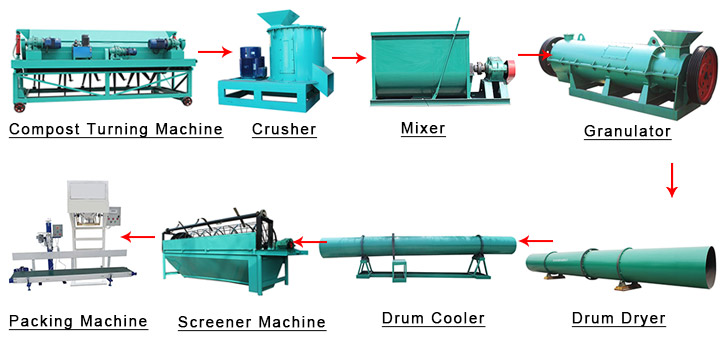

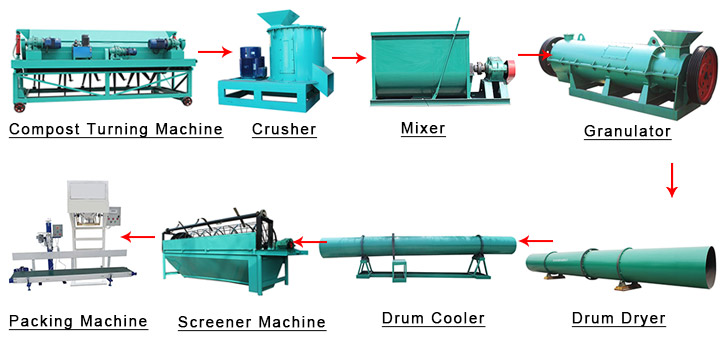

The organic fertilizer production line is mainly divided into two parts, fermentation and granulation. The equipment used mainly includes granulator equipment, animal manure treatment system, semi wet material crusher, roll extrusion granulator, drying system and other

fertilizer equipment. The treatment process of organic fertilizer equipment is a little complicated, and the main influencing factors of fermentation part are: microorganism, carbon nitrogen ratio, water content, pH value, aeration control, etc. Because a bad control of one factor will affect the fermentation effect, the characteristics of organic raw materials are light, rough and low binding rate.

The granulation part and the inorganic fertilizer part are also very different, because the organic material and the inorganic material are different, and the use of the inorganic fertilizer is based on the chemical reaction, generally containing only one or two specific elements, which has a great effect on the lifting of crops in a short time, but long-term forgetting will cause certain soil elements and plant growth environment The raw materials used in organic fertilizer are agricultural wastes, such as straw, household garbage, etc., which play a certain role in the sustainable development of the environment.

The

organic fertilizer production line will be gradually developed in recent years, and will be widely used in green food, vegetable planting and municipal greening. Although the production process of organic fertilizer production line is complex, in general, its production cost and risk are relatively small, and its raw material selection is very wide. As for the difference between organic fertilizer equipment and inorganic fertilizer equipment, you can choose the equipment according to the factors such as annual output, fermentation mode, mechanization degree, etc.