Now we are advocating ecological agriculture. Organic green agricultural products are popular, and organic fertilizers are gradually put into use. Organic fertilizers are divided into farmyard manure, green manure, straw manure, commercial organic manure and other categories. In addition, peat, peat, Tanghe River garbage and other wastes are also important sources of organic fertilizers, which help to cultivate soil and improve crop quality. With the rapid development of livestock and poultry breeding industry, a large number of excrement and sewage have been produced. The harmful elements in these feces are seriously over the standard, so it is difficult to deal with them in the traditional way. In view of this situation, people have developed an

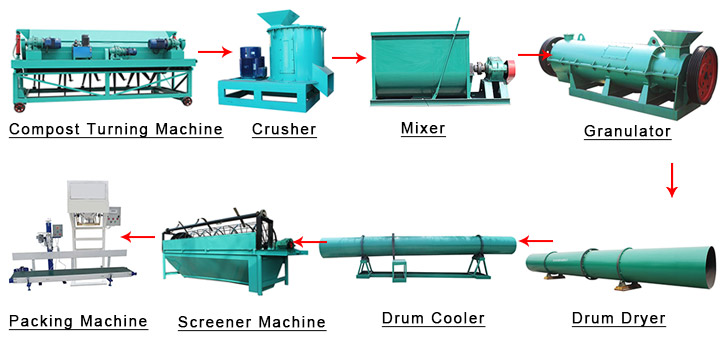

organic fertilizer production line with movable and high-efficiency solid-liquid separation technology as the core, which integrates high-efficiency mixer, windrow turner, granulator and other fertilizer production equipment.

The

fertilizer equipment needed for organic fertilizer in livestock and poultry breeding industry includes:

1. Dumper: it uses animal manure, domestic garbage, sludge, crop straw and other organic solids for industrial fermentation treatment. The equipment ferments the uniformity of fermentation materials. So that the front of the fermentation tank can be freely put or taken out of the fermentation mode, feces and other waste can be retained for a long time.

2. Wet material pulverizer: it is a pulverizing equipment for pulverizing high humidity and multi fiber materials. Using high-speed rotating plate, it can crush fiber with good granularity, high efficiency and high energy. Semi wet material crusher is mostly used in the production and processing of organic fertilizer. It has a good effect in crushing chicken manure, humic acid and other raw materials.

3. The mixer has fast mixing speed and good uniformity. It can mix and add 30% viscous materials of liquid. When it works, there are two rotors with opposite rotation stirring in the middle. Because the blade has many special angles regardless of the shape of the material. How about size and density. Can mix quickly and effectively. Adopt the lower opening door to discharge the material quickly, with less residue.

4. Organic fertilizer granulator is a molding machine that can make materials into specific shapes. It is widely used in the production of organic fertilizer, bio organic fertilizer and other fields. According to the structure and working principle, it can be divided into roll extrusion granulator, disc granulator, round throwing granulator, new organic fertilizer granulator, etc

5. The roller screen adopts the combined screen, which is convenient for maintenance and replacement. The structure of the machine is simple, the operation is convenient and the operation is stable. The roller screen is mainly used for the separation of finished products and returned materials. It can also realize the classification of finished products, so that the finished products can be classified evenly.

6. The packaging machine is mainly composed of material inlet, feeding mechanism (gate), weighing bucket, bag clamping mechanism, frame, air suction outlet, pneumatic system, sensor, control box, conveying and sewing mechanism, etc.

7. Conveyor: configure belt conveyor, bucket elevator or screw conveyor according to the actual needs of customers.