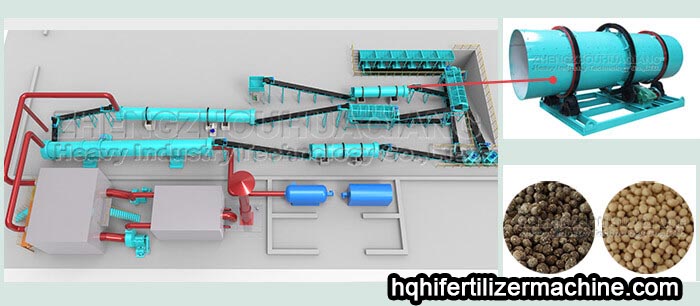

A certain amount of water or steam is added to the

drum granulator to form a suitable solid-liquid ratio. The solid-liquid material is rolled and coated under the action of the equipment to form particles of a certain size.

Details of organic fertilizer production by drum granulator

- 1. The fertilizer granulator machine should be equipped with two mixing powder bins to be pelletized, so that the granulator does not need to stop when changing the formula.

-

- 2. Before the organic fertilizer raw material enters the drum granulator, a rate iron removal device must be placed to protect the granulator from being damaged by some other impurities in the raw material.

-

- 3. Drum granulator should be placed on cooler, crusher should be placed under cooler.

-

- 4. In order to make the organic fertilizer particles fall to the bottom of the bin from a high place, so as not to damage the bottom of the bin, a vertical spiral chute should be installed in the bin to slow down the impact force.

-

- 5. The finished product of granular organic fertilizer should be packed in the finished product warehouse, and attention should be paid to the preservation environment to avoid affecting the effect of organic fertilizer.

The above is the

granulator machine for fertilizer in the process of operation need to pay attention to some details, not only to save a small amount of power input, to achieve effective cost reduction, but also to achieve task efficiency improvement, convenient and effective, the effect is satisfactory. It has the characteristics of high strength, good appearance quality, corrosion resistance, wear resistance, low energy consumption, long service life and convenient operation and maintenance.