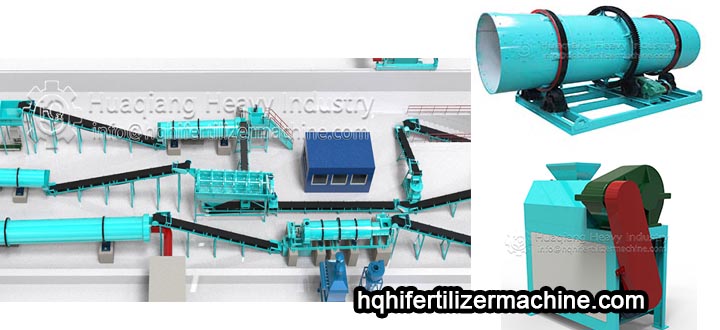

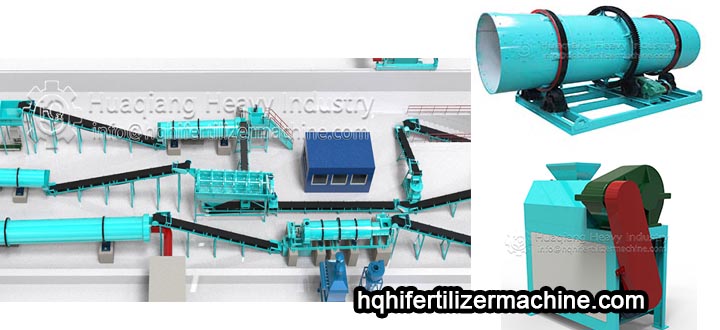

The common granulating machines for compound fertilizers are roller granulator and drum granulator. After granulation, the materials can be stored for longer and are not easy to agglomerate. The following article mainly focuses on these two fertilizer granulators. Give a detailed introduction.

The

roller granulator is composed of a roll of opposite rotation direction, which are installed side by side with small spacing. Generally, one roll is fixed and the other rotates relatively. The surface of each roll is engraved with a certain number of die holes. The powdery material enters the hopper. With the continuous rotation of the rollers, the material enters the arc triangle between the two rollers and is gradually compressed. When it reaches the geometric centerline of the opposite rollers, the fertilizer in the die hole receives the maximum pressure and is compressed into fertilizer. When the roller rotates through the centerline, there is a slippage between the particles and the die hole. Under the action of gravity, the fertilizer particles fall off from the die hole. This extrusion process is purely a volumetric compression, and the magnitude of the force is mainly related to the roller radius, die hole size and fertilizer filling degree. In addition to the full stirring before granulation and the screening in the subsequent process, there is no heating in the whole process production, and no drying and water removal are required, so that the material does not undergo chemical reactions, and the processing is very convenient.

The main granulating part of the

drum granulator is an inclined rotating cylinder, with a retaining ring at the inlet to prevent overflow of the feed, and a retaining ring at the outlet to ensure the depth of the material layer. The mixed materials are mixed by the mixing equipment and fed into the cylinder automatically and quantitatively, and contact with the sprayed droplets. As the cylinder continues to roll, the materials gradually become balls, the materials are continuously added, and the pellets are continuously discharged and continuously performed. The drum

fertilizer granulator machine is suitable for the production of high-concentration compound fertilizer. When it is used to produce low-concentration compound fertilizer, it will return too much material, the particles are not round, and the product quality is not high. The drum granulator relies on the granulation temperature to increase the amount of liquid phase in the granulated material, which promotes the granulation of the material at a lower water content, provides convenience for drying, and significantly reduces energy consumption.