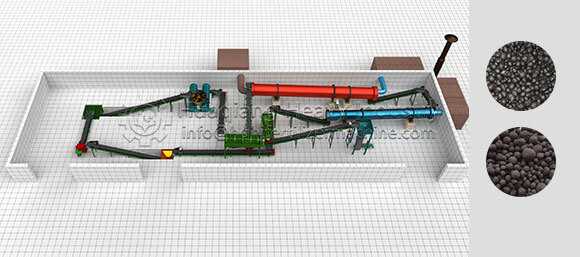

Stepping into an organic fertilizer production workshop, you'll find granulation to be the most captivating process. This process transforms loose, powdery fertilizer into well-formed granules, with different granulation equipment showcasing their unique capabilities.

In an organic fertilizer production line, granulators reshape powder into granules using physical or chemical methods. Among them, the double roller press granulator employs a unique "dry" process. This method offers significant advantages: no drying step is required, making it particularly suitable for processing heat-sensitive materials, resulting in lower energy consumption and superior granule hardness.

In contrast, the organic fertilizer disc granulator presents a different kind of charm. The tilted disc rotates slowly, causing fine powder to agglomerate and enlarge under the action of a binder. This "wet" granulation method allows operators to directly control granule size, easily achieving the ideal particle size by adjusting the disc's tilt angle and rotation speed.

Choosing the appropriate granulation process requires comprehensive consideration of raw material characteristics, production capacity requirements, and product standards. Roller granulation produces uniform granules, while disc granulation produces beautifully spherical particles; each type of equipment plays an irreplaceable role in organic fertilizer production.

High-quality organic fertilizer granules not only enhance the commercial value of fertilizers but also ensure their slow-release effect in the soil. These seemingly simple granules embody the wisdom of modern technology in promoting sustainable agricultural development, laying a solid foundation for fertile soil and abundant harvests.