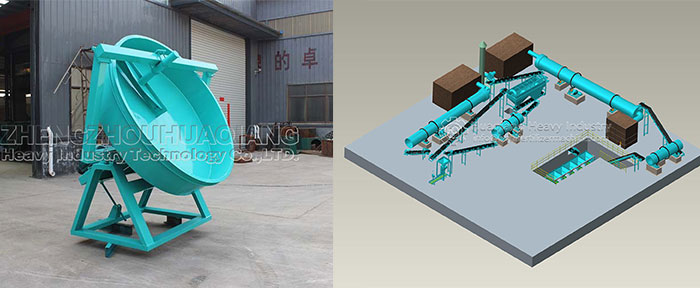

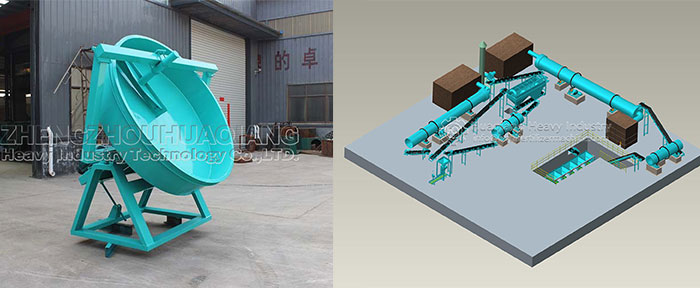

The disc granulator is one of the compound

fertilizer granulator machine products of Zhengzhou Huaqiang Heavy Industry. It has a new and reasonable structure, reduced weight, lower height, flexible and convenient process layout, and is suitable for the transformation of old factories. So how to maintain and maintain the compound fertilizer equipment disc granulator in the daily operation process? The following is a detailed introduction to you:

1. When driving on uneven roads slow down and reduce the load on the steering gear.

2. After 500 hours of use, change the lubricating oil once. The oil level in normal operation should not be lower than the center line of the oil standard. If it is below the center line, please replenish it quickly. Change the oil every 3000 hours after use.

3. Always check the status of the protective covers on both sides of the steering gear and the protective cover connecting the upper part of the steering gear to the universal cross shaft. The damage of the sheath is the main factor leading to the early wear and damage of the steering gear. After the sheath is damaged, water, dust and sand enter the steering gear through the damage, destroying the grease film of the rack and pinion, causing rust and abnormal wear inside the steering gear. If the water and sand inside are not immediately disposed of, the steering wheel will be scrapped in the short term. Therefore, check the status of the dustproof sheath at least once a month. If the sheath is found to be damaged, it must be replaced immediately, and the steering gear must be thoroughly inspected and maintained before replacement.

4. After adjusting the front toe of the four-wheel alignment and changing the steering rod, pay special attention to the fact that the protective cover cannot be distorted or assembled improperly, otherwise it will cause damage to the protective cover.

5. Because the grease will gradually become dirty and deteriorated during use, the lubricating ability will be reduced; at the same time, the substances under wear will gradually increase, and the phenomenon of abrasive wear will become more and more serious, which will increase the wear of the steering gear. Every 100,000 kilometers or so, the steering gear should be thoroughly maintained, cleaned, and refilled with grease.

6. The operating conditions of the steering gear are bad and the load to bear is large. Special grease must be used for the disc

granulator machine for fertilizer. Ordinary grease cannot meet the requirements for use.

7. The clearance of the steering gear will gradually increase during use. If the left and right idle stroke of the steering wheel exceeds 15 degrees, the steering gear must be inspected. If the gear rack is abnormally worn and severely worn, the steering gear assembly must be replaced; if there is no abnormal wear, but the gap is too large and can be adjusted. The adjustment should be carried out by trained professionals at the service station. After adjustment, ensure that the steering wheel can be driven to the left and right to the extreme position, with uniform strength and flexible rotation.

8. Do not arbitrarily carry out the maintenance and maintenance of the steering wheel in a roadside shop with poor equipment and low technical level. Improper adjustment of the steering gear may cause jamming, endangering driving and personal safety.