Organic fertilizer is made of poultry manure as raw material, combined with fermentation bacteria, straw and other auxiliary materials, and processed into organic fertilizer by traditional fermentation methods or organic fertilizer production equipment. For commercial organic fertilizers sold on the market, the two more popular forms of finished organic fertilizers are powder and granular. What is the processing technology of powdered organic fertilizer and granular organic fertilizer? Which of these two forms is better?

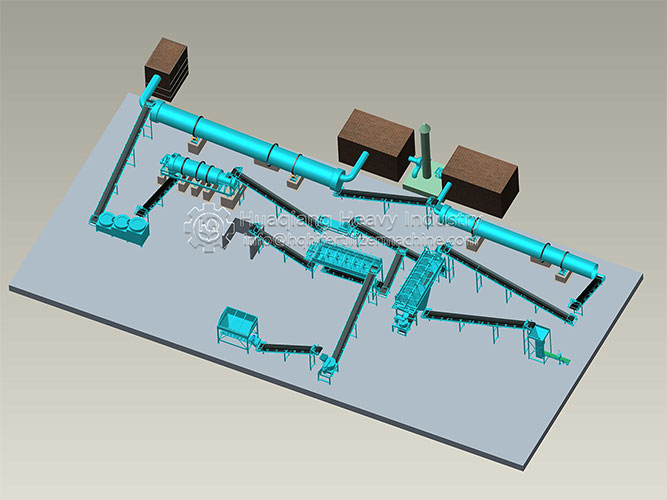

Granular organic fertilizer processing technology:

The equipment used in the processing and production of granular organic fertilizers are: fermentation turning and polishing machine, grinder, disc granulator machine for fertilizer, screening machine, packaging machine

The successfully fermented fertilizer is pulverized with a pulverizer, and then a disc fertilizer granulator machine is used for the production of organic fertilizer particles, and then the organic fertilizer particles are sieved with a sieving machine, dried, and finally transported to the lower silo for packaging Weigh and seal.

Processing technology of powdery organic fertilizer:

The powdery organic fertilizer production line needs to purchase equipment: fermentation turning and polishing machine, grinder, packaging machine, etc.

Advantages of powdered organic fertilizer: less investment in production and manufacturing;

Better fusion with roots, wider spreading range, fast root and soil fertility effect and fast absorption

Disadvantages:

It is easy to raise dust, damp and agglomerate in the process of application.

Advantages of granular organic fertilizer:

Some inorganic ingredients can be added to chemical fertilizers to enhance fertility. It is more convenient to apply.