Pig manure

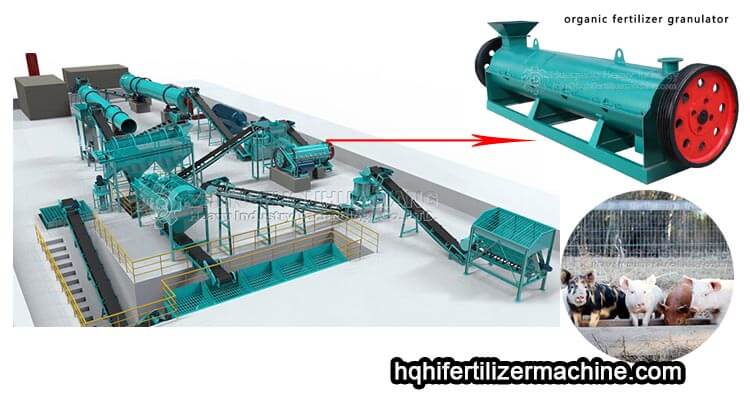

organic fertilizer production line can be divided into raw material pretreatment, aerobic fermentation, fertilizer granulation processing. Organic fertilizer equipment needs fermentation tipper, crusher, screening machine, mixer, granulator, dryer, cooler, screening machine, coating machine, packaging machine, conveyor and other equipment.

1. Pre fermentation

20 tons of cow manure, 10 tons of chicken manure and 20 tons of pig manure were added into the mixed pre fermentation device (imported from Holland) to inoculate, fully mix and pre ferment organic materials.

2. Main fermentation

Aerobic fermentation with biological bacteria was used. The fermentation temperature was controlled at 50-60 ℃. After the fermentation, the color was dark brown, no fecal odor but composting smell.

3. Granulation of pig manure organic fertilizer

(1) The ingredients (rice straw, straw, bean cake, bone powder, hoof horn powder, etc.) are crushed, and the organic fertilizer is crushed at the same time.

(2) The formula of raw material compounding and inorganic raw material is mixed according to different series of products. Mix well in the mixer. If the proportion is 12%, about 12 tons.

(3) For the organic materials with high C / N ratio and low moisture content of straw powder or peat, the addition amount is 6 tons / day of charcoal, 6 tons / day of straw carbon and 18 tons / day of straw straw straw straw. After treatment, the moisture content of raw materials is 60% - 65%, and the C / N ratio is 20-30. The added substance must be broken thoroughly.

(4) It is granulated by organic fertilizer granulator, dried and dehydrated by dryer, and screened by screening machine. The finished organic fertilizer is ready and can be packed and stored.