Making cow manure into organic fertilizer is a new project of energy conservation and environmental protection. The main process of making cow manure into organic fertilizer is fermentation, tossing, crushing, drying, cooling and granulation.

Treatment method of cattle manure organic fertilizer production line:

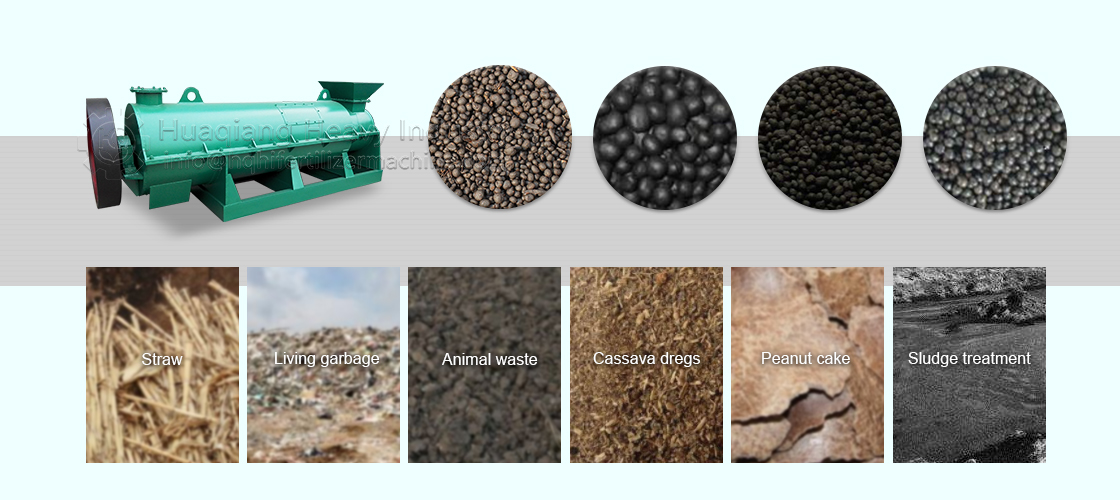

- 1. The cow manure is collected, mixed with hay and rotten silage to make compost, in which biological bacteria are added to make it ferment, fertilizer equipment is used to make it fully ferment in the fermentation process, and tank type dumper is used for the fermentation of cow manure in the early stage Ingredients are crushed and mixed. The composted materials, inorganic fertilizers such as N, P, K, and other additives are crushed, proportioned and mixed by material crusher and horizontal crusher in a certain proportion.

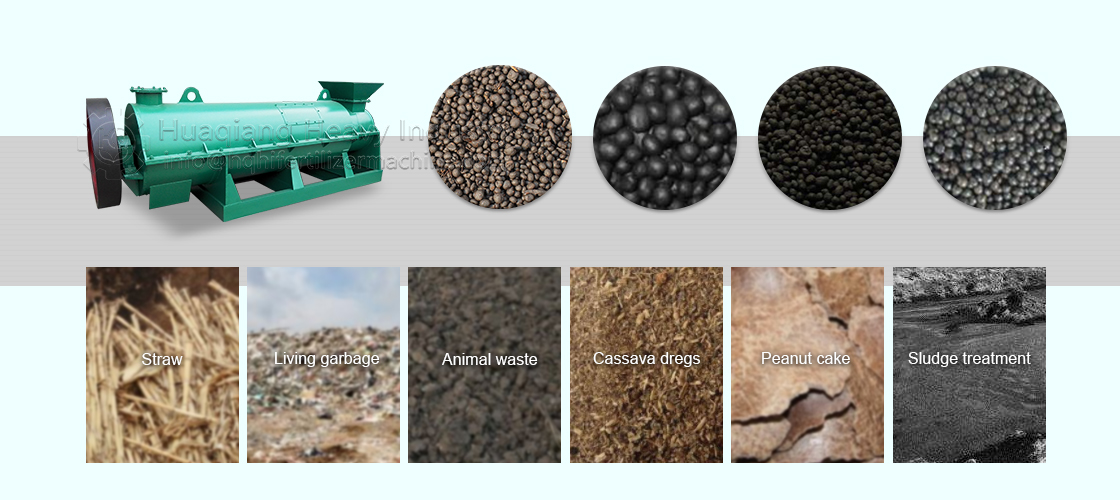

- 2. A new type of organic fertilizer granulator is used to granulate materials. The output of the screening and return system from the pelletizing and forming system of the granulator has certain differences in the material diameter, which requires screening and classification. The selected rotary screen requires small vibration, low noise, convenient screen changing, and is equipped with screen surface cleaning device. It is recommended to equip with an automatic return system to screen the unqualified large and small particles, which are transported by the belt elevator, re crushed and then sent to the granulator for further processing. Granulation is helpful to improve the continuous operation ability of organic fertilizer production line.

- 3. The sieved particles are sent to the dryer to further remove the moisture and meet the standard requirements of moisture content of organic fertilizer.

- 4. The cooling machine is used to cool the granular materials, which is helpful for the storage and quality of the granules.

- 5. The cooled granular materials are transported to the finished product warehouse by belt conveyor, and the quantitative weighing and packaging of granular materials are realized by automatic packing scale.