The

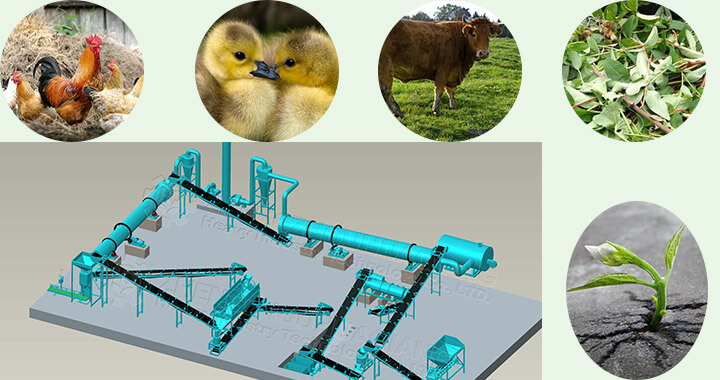

organic fertilizer production line can solve the problem of cow manure environmental protection. We want to set up a cow manure organic fertilizer plant. Under different configuration schemes, the finished products are different and the input costs are also different. Here is an introduction to the process of making organic fertilizer from cow manure and the production process of cow manure organic fertilizer.

In the process of producing organic fertilizer from cow manure and the production process of organic fertilizer from cow manure, it is recommended to adopt aerobic fermentation treatment, which can be fermented with fermentation agent, so as to better the crops, and mix the cow manure with straw, sawdust, mushroom dregs, etc. in proper proportion (80-90% of the manure, 10-20% of the others). During the fermentation process, proper oxygen supply and turning over should be paid attention to, and the temperature should be controlled at 55-65 ℃. The water content of fermentation materials should be controlled at 60-65%.

Production technology of cow manure organic fertilizer

1. The method of adjusting material moisture: the moisture content of fermented cow manure and other animal manure should be controlled at 40-65%.

Judge whether the moisture is suitable or not: hold a handful of materials tightly, see the watermark at the finger joint but do not drop water, and it will be scattered when landing. In general, the whole fermentation process can complete the complete deodorization, fermentation, decomposition, insecticidal sterilization and so on in 5-7 days.

2. Start up temperature of organic fertilizer production: the start-up temperature should be above 15 ℃ (it can be operated in four seasons, not affected by the season, and it is better to ferment indoors or in the greenhouse in winter), and the fermentation temperature should be controlled below 70-75 ℃.

3. Mix well and ventilate: the production of organic fertilizer by cow dung fermentation requires good (consumption) oxygen fermentation. Therefore, during the operation process, oxygen supply measures should be increased to achieve mix well, turn frequently and ventilate properly. Otherwise, it will cause anaerobic fermentation and produce odor, which will affect the effect of fertilizer.

4. Fermentation completion: generally, 48 hours after the cow dung is piled up, the temperature rises to 50-60 ℃, and the third day can reach above 65 ℃. Under this high temperature, it can be turned over once. Generally, there will be two times of high temperature above 65 ℃ in the fermentation process. Turning over twice can complete the fermentation, and the fermentation can be completed within a normal week. The material was dark brown, and the temperature began to drop to normal temperature, indicating that the fermentation was completed.

Cost of small and simple cattle manure organic fertilizer production line: within 100000 yuan, the organic fertilizer production line configured for each customer is different. The low configuration of cow manure organic fertilizer production line only requires pulverizer, mixer, granulator, screening machine and packaging machine. This is a basic configuration, and equipment can be added according to the actual needs and requirements of customers. Therefore, the price of the whole cattle manure organic fertilizer production line varies from tens of thousands to hundreds of thousands.