The working principle of the

roller granulator is that the belt and pulley are driven by the motor and transmitted to the driving shaft through the reducer, and they are synchronized with the passive shaft through the split gear and work in the opposite direction. The materials are added from the feeding hopper, extruded by rollers, demoulded into balls, and transported to the crushing screen studio to screen and separate the finished particles (balls), and then the returned materials are mixed with the new materials, and then granulated.

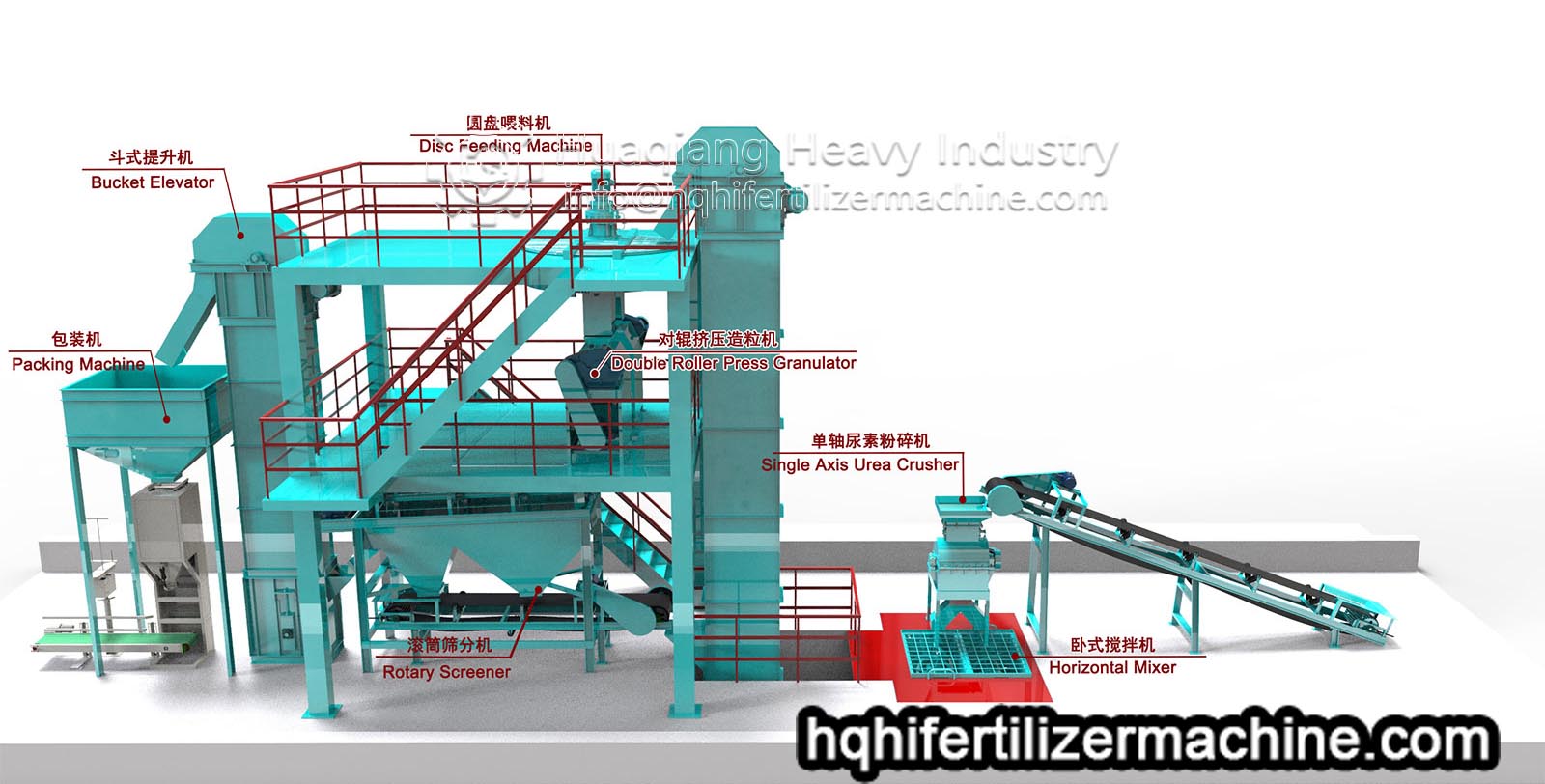

The technological process of the production line of fertilizer by roller granulation: automatic batching system → fertilizer mixer → uniform feeder → roller granulator → screening machine → packaging machine.

The whole double roller granulator is divided into four parts

1. Frame part: all working bodies of roller granulator are fixed on the frame. The frame of the

fertilizer granulator machine is made of medium carbon steel plate and channel steel by welding. Through strict quality control and specific process requirements, the purpose of the machine is achieved. Lifting holes are set in the middle of the four corners of the frame for use in loading, unloading and transportation.

2. Transmission connection part: the motor drives the belt pulley, V-belt and reducer to drive the machine head. In addition, the chain wheel and chain constitute the transmission chain and transmit to the crushing and separating work part. The transmission reducer and the working part of the machine head are meshed and driven by nylon pin coupling.

3. Working part of the machine head: the transmission wheel is transmitted to the transmission roller shaft through the pin coupling. The synchronous operation of the pair of rollers is ensured by a pair of open gears, and both sides of the active and passive shafts.