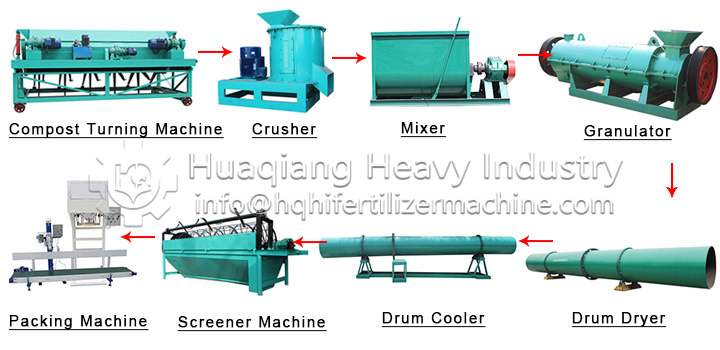

Pig manure organic fertilizer production line is a complete set of natural organic pig manure organic fertilizer machine, which uses fresh pig manure as raw material and through a series of processing. There are two steps for the processing of pig manure organic fertilizer: pre fermentation and treatment and deep granulation. The supporting equipment of pig manure bio organic fertilizer needs fermentation windrow turner, organic fertilizer crusher, roller screen machine, horizontal mixer, fertilizer granulator, rotary dryer, cooler, screen machine, coating machine, packaging machine, conveyor and other

fertilizer equipment.

Process flow of pig manure

organic fertilizer production line

In the early stage of fermentation, a fermentation trough with a width of 3 meters and a length of 50 meters (which can ferment more than 200 tons of raw materials) or a machine with multiple tanks shall be built, and then the raw materials (excrement, biogas residue and straw) shall be piled up in the fermentation trough. 1 kg of humic agent is mixed with 20 kg of water and mixed in the raw material pile. 1 kg of humic agent can ferment 1 ton of raw materials. In the fermentation process of pig manure fertilizer, observe the controllable factors in the fermentation process at any time, such as temperature, water content, pH and other conditions. Generally, fermentation can be completed in 7-10 days, without odor. The color of raw material is black brown or black, which means maturity.