Bio-organic fertilizer production lines involve several stages. Each stage uses machinery and microbial fermentation, so strict safety rules are essential for efficiency and worker safety.

1.Raw Material Pre-Treatment

Risks: Raw materials (like manure, crop stalks) can contain pathogens and harmful gases (ammonia, hydrogen sulfide).

Precautions:

Workers need dust masks, gloves, and protective clothing to avoid direct contact with decaying material.

If the crusher jams, stop the machine before clearing it.

2.Fermentation Process

Risks: High-temperature fermentation can produce flammable gases. Improper compost turning machine operation can cause injuries.

Precautions:

Keep fermentation tanks or piles well-ventilated to stop harmful gas build-up.

Keep a safe distance from the compost turner while it's working.

3.Crushing and Mixing

Risks: High-speed crushers can throw material or malfunction.

Precautions:

Before starting, check that crusher blades are tight to prevent them flying loose.

Only clean the mixer after it has stopped.

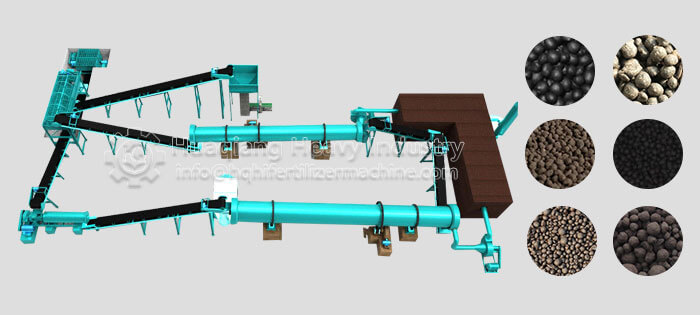

4.Granulation

Risks: High pressure in granulators can pinch fingers if mishandled.

Precautions:

Never adjust roller gaps or clean dies while the machine is running.

Keep clear of rotating disc granulators; loose clothing could get caught.

Bio-organic fertilizer production has safety risks at every step. Companies must set strict rules, provide protective gear, and give regular safety training to ensure efficient, stable, and safe operation.