With the growing emphasis on green agriculture and sustainable development, the demand for organic fertilizer continues to rise. In this context, the new type organic fertilizer granulator has become an ideal choice for modern organic fertilizer production, thanks to its efficiency, energy savings, and eco-friendly features. It helps businesses improve productivity and competitiveness.

1.Efficient Production, Increased Capacity

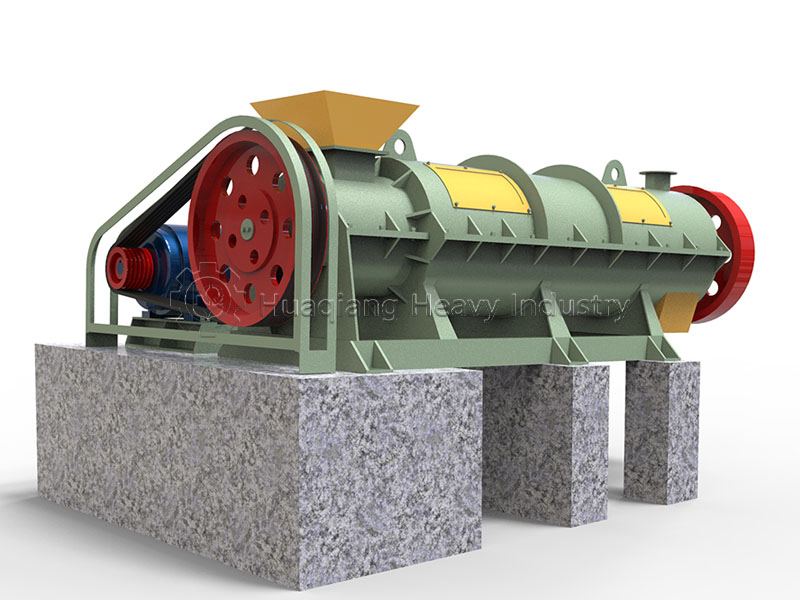

The new type organic fertilizer granulator uses advanced mechanical principles and an intelligent control system to enable continuous automated production. With strong processing capabilities, it quickly turns powdered organic materials into uniform granules, significantly boosting efficiency, reducing labor costs, and meeting large-scale production needs.

2.Energy Efficient and Eco-Friendly, Lower Operating Costs

The equipment incorporates energy-saving technologies and an optimized power system, reducing energy consumption by more than 20% compared to traditional machines. Additionally, the granulation process requires no chemical binders, avoiding secondary pollution and meeting environmental standards. The resulting granules are strong, less prone to breaking, and easy to store and transport, reducing waste.

3.Highly Adaptable, Wide Range of Applications

The new type organic fertilizer granulator works with various raw materials, such as livestock manure, straw, and sludge. It allows adjustments to processing parameters based on material characteristics, ensuring consistent granule quality. Compact, user-friendly, and easy to maintain, it is suitable for large, medium, and small organic fertilizer production operations.

With its efficiency, energy savings, and environmental benefits, the new type organic fertilizer granulator is becoming a key equipment in the industry’s upgrade. Investing in a high-performance granulator not only improves product quality and production efficiency but also delivers long-term economic and environmental benefits for businesses.