A bio-organic fertilizer production line turns organic waste into effective fertilizer. Getting the key steps right is essential.

1.Raw Material Pre-Treatment

Keep moisture between 50-60%. Add bulking agents if it's too wet.

Use a crusher to break large chunks down to 3-5 cm pieces.

Mix raw materials to achieve a carbon-to-nitrogen (C/N) ratio of 25-30:1.

Ensure thorough mixing for optimal fermentation later.

2.Fermentation Process

Pile Building: Make piles 1.2-1.5 meters high and 2-3 meters wide for good airflow.

Temperature Control: Check pile temperature regularly. Keep the high-temperature phase (55-65°C) going for at least 5-7 days.

Turning: Turn the pile using a compost turning machine whenever temperature goes over 70°C. Do this every 2-3 days usually.

Moisture Control: Maintain 50-60% moisture during fermentation. Add water if needed.

Duration: Fermentation typically takes 15-30 days. It's done when the material has no foul odor and turns dark brown.

3.Post-Processing

Crushing and Screening: Crush the material to the required fineness and screen out any undecomposed bits.

Adding Functional Microbes: Inoculate with specific microbes like nitrogen-fixing or phosphorus-solubilizing bacteria, depending on the product.

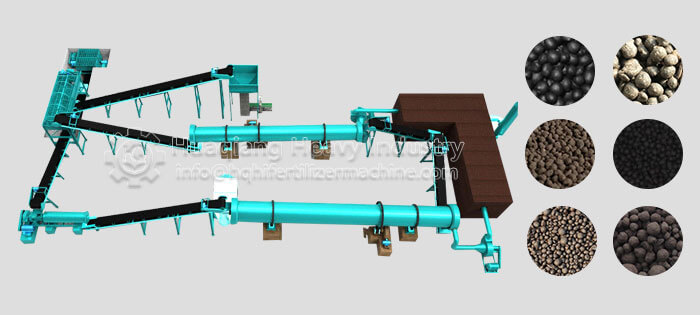

Granulation: Adjust the fertilizer granulator settings to produce uniform, strong-enough particles.

Low-Temperature Drying: Dry at temperatures ≤80°C to protect the beneficial microbes.

Packaging and Storage: Use moisture-proof bags and store in a cool, dry place.

Mastering these key steps helps producers make better quality fertilizer more efficiently, saving energy and costs, giving them an edge in the competitive market.