In large-scale organic fertilizer production, rotary drum granulators, as the core type of organic fertilizer granulator, have become the "central equipment" of rotary drum granulation production lines due to their excellent adaptability and production capacity advantages.

The core advantages of rotary drum granulators are "wide adaptability and high production capacity." Compared with other organic fertilizer granulators, they have a higher tolerance for raw material moisture and viscosity, and can process diverse materials such as composted livestock and poultry manure and straw fermentation materials with a moisture content of 20%-30%, without the need for excessive fine pre-treatment. The equipment's molding rate is stably above 90%, and the hourly production capacity of a single unit can reach several tons to tens of tons, perfectly meeting the needs of large-scale production.

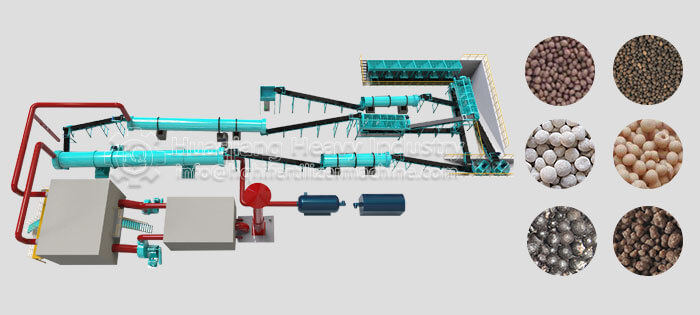

The efficient operation of the rotary drum granulation production line relies on the precise coordination of the rotary drum granulator with other equipment. The pre-treated raw materials are uniformly mixed by the batching and mixing system and then directly fed into the rotary drum granulator, while water or binders are precisely added through a spraying device; after granulation, the granular materials directly enter subsequent equipment such as dryers, coolers, and screening machines, forming a complete closed-loop process of "batching - granulation - post-processing."

Whether producing pure organic fertilizer or organic-inorganic compound fertilizer, the rotary drum granulation production line can achieve diversified output with the flexible adaptability of the rotary drum granulator. It not only lowers the operational threshold for large-scale organic fertilizer production but also ensures the stability of finished product quality.