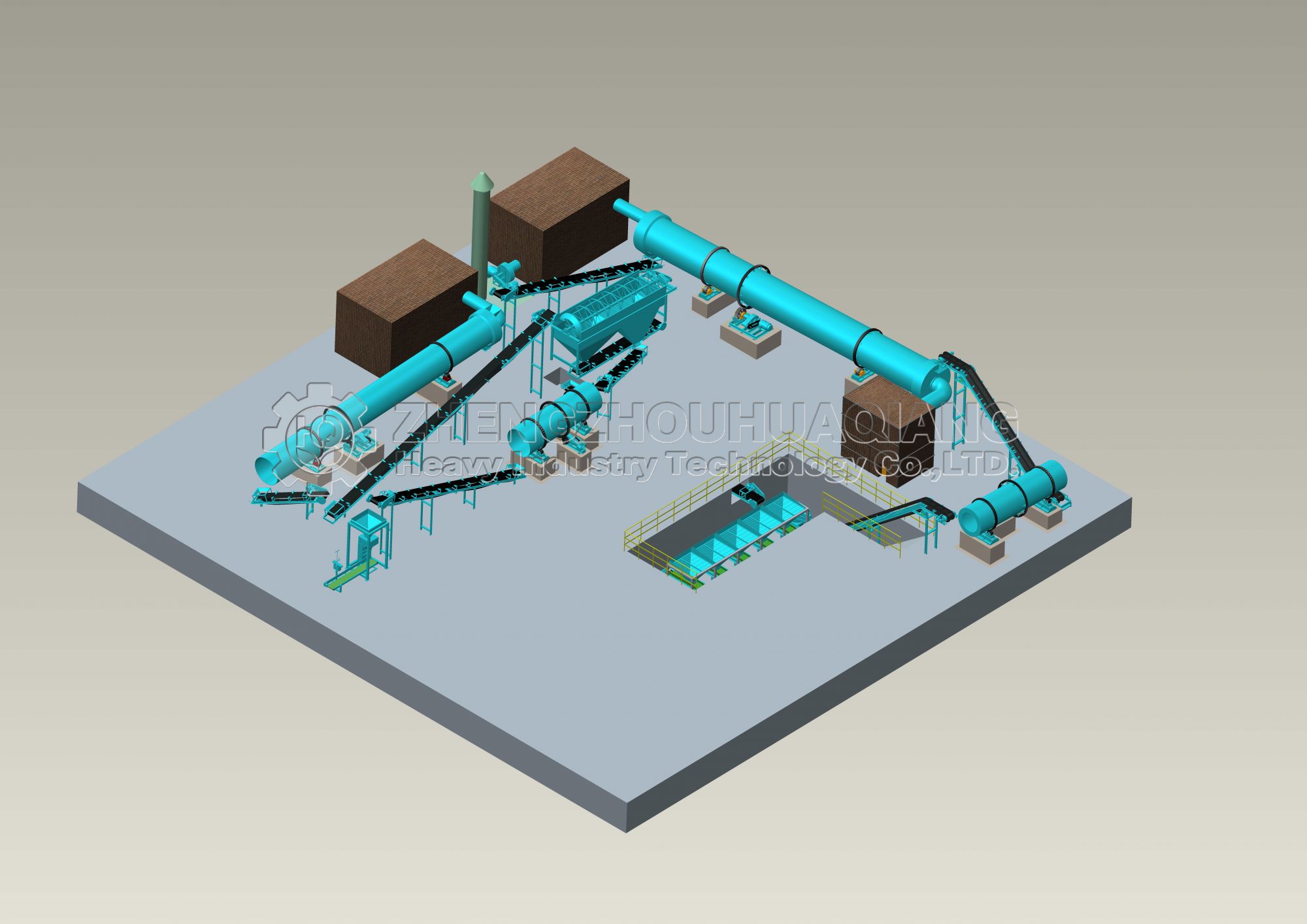

Process flow of organic fertilizer production line with an annual output of 100000 tons:

The organic fertilizer production line is mainly used to measure the organic wastes of animal manure such as cow manure, sheep manure, pig manure, chicken manure, sludge, rice straw and corn straw in the material farm after fermentation and ripening. After crushing and screening, the organic wastes with about 30% - 35% water content, together with the raw materials of binder (bentonite and humic acid) and other components to be proportioned in the proportioning and mixing system according to the proportioning requirements (biological organic fertilizer can be produced by adding functional bacteria, and organic and inorganic fertilizer can be produced by adding nitrogen, phosphorus and potassium (the total nutrient content is less than 15%)) batching and mixing. The fully mixed materials are evenly and continuously fed into the granulator by the belt conveyor, rounded into spherical particles by the polishing and shaping machine, dried by the dryer at low temperature and large air volume (≤ 65 ℃) and then cooled, screened After coating, the finished product particles are transported to the finished product silo by belt, measured by the computer quantitative packaging system, packaged and put into storage.

The organic fertilizer production line equipment produces bio organic fertilizer by composting to improve the nutrients required by crops. The organic fertilizer produced by the composting technology introduced by the organic fertilizer production line equipment manufacturer is fermented by biological bacteria. The organic fertilizer after fermentation and crushing contains certain inorganic nutrients, a large amount of organic matter and trace elements, Therefore, this bio organic fertilizer is especially suitable for horticultural crops and soil with long-term application of chemical fertilizer.