In the future agricultural development trend of paying more and more attention to quality and health, commercial organic fertilizer will be gradually marginalized. In the future, on the premise of solving the transportation cost of straw, the fermented and decomposed straw is a promising organic fertilizer source.

The

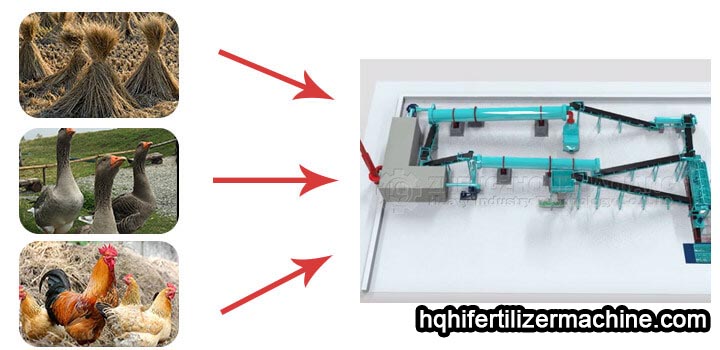

organic fertilizer production line from waste straw is a practical problem with universal significance. For agricultural producers, organic fertilizer plays an irreplaceable role in enriching the soil and improving the quality of products. Organic fertilizer producers can recycle the straw nearby (generally only need to transport the vehicle, straw itself does not need cost), and then the straw is fermented. After the straw is crushed, urea and fast-growing bacteria are added. When the temperature is suitable in summer, the fermentation can be completed in a week or so.

The process of making commercial organic fertilizer from waste straw

- 1. Stacking of ground strips, using a ground cpmpost turning machine, or feeding materials in a fermentation trough, using a tank type compost turning machine

- 2. Evenly sprinkle the fungicide, turn the pile of fermentation to achieve heating, odor, rot, and kill mixed fungus grass seeds

- 3. Fermentation for 7-12 days, how many times the piles are turned according to different temperatures in different places

- 4. Completely fermented and cooked, out of the pond (ground type directly piled up with a forklift)

- 5. Use a grading sieve to screen the thickness, (screened powdery fertilizer can be sold directly)

- 6. The crushed large pieces are crushed with a crusher and returned to the classification screen

- 7. Mix the required trace elements with a mixer

- 8. Granulation with a granulator

- 9. Feed into dryer and cooler

- 10. Automatic packaging machine packaging and sale