.jpg)

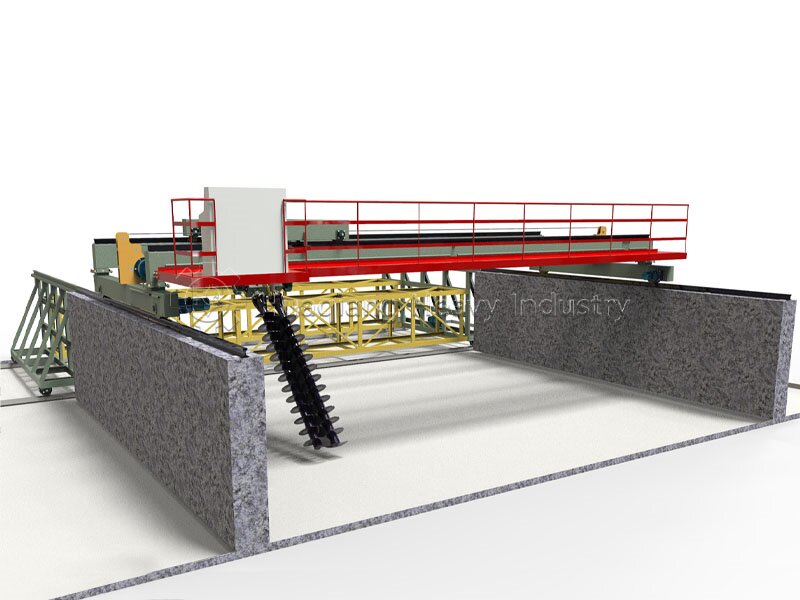

A twin-screw compost turner utilizes a double-helix structure to stir and turn materials, a process widely used in the fermentation process of organic fertilizer production. Its core operating principle is that two symmetrically distributed spiral shafts rotate at high speed. The spiral blades lift the material from the bottom and turn it to the sides. This process allows the material to fully come into contact with air, regulating its temperature and humidity, creating a suitable environment for microbial growth and metabolism, and thus accelerating its composting and fermentation.

This equipment adopts a double-screw collaborative operation design, with a wide turning range and uniform mixing. Compared with a single-screw compost turner, it can more effectively break up the compacted layer of the material and improve the air permeability of the material. It is suitable for strip-type or trough-type fermentation operations in medium and large-scale organic fertilizer production enterprises.

What raw materials can be fermented by the double-screw compost turning machine?

The double-screw compost turning machine has good adaptability to a variety of organic materials and can efficiently ferment the following raw materials:

1.Livestock and poultry manure

This includes chicken, pig, cow, and sheep manure. Rich in organic matter and nutrients like nitrogen, phosphorus, and potassium, these manures are high-quality raw materials for producing organic fertilizer. The powerful turning of the twin-screw compost turner allows the manure to fully come into contact with air. The high temperatures during the fermentation process kill pathogens, insect eggs, and weed seeds, eliminating odor and transforming it into a harmless organic fertilizer.

2.Crop straw

Such as corn straw, wheat straw, rice straw, etc. Straw contains a lot of cellulose, hemicellulose and lignin. The spiral blades of the double-screw compost turning machine can tear and stir the straw, mix it evenly with other organic materials, promote the degradation and maturity of the straw, convert it into organic matter in organic fertilizer, and improve the fertility of organic fertilizer.

3.Industrial organic waste

These wastes include wine lees, vinegar lees, sugar residue, Chinese medicine residue, and slaughterhouse waste. These wastes have high water content and are easily corrupted. The double-screw compost turner can reduce the moisture content of the materials through continuous turning, promote the growth of beneficial microorganisms, achieve harmless treatment and resource utilization of wastes, and reduce environmental pollution.

4.Edible mushroom residue

The residue from mushroom cultivation is rich in mycelium and underutilized nutrients. The double-screw compost turning machine can ferment the residue with other organic materials, fully releasing and converting the nutrients in the residue into high-quality organic fertilizer.

5.Municipal organic waste

The double-screw compost turning machine can centrally process these scattered wastes, such as kitchen waste and landscaping waste (dead branches and leaves, weeds, etc.). Through physical crushing and biological fermentation during the turning process, it can transform them into organic fertilizer raw materials, reducing the amount of urban waste landfilled and realizing resource recycling.

Equipment composition of double-screw compost turning machine

The double-screw compost turning machine consists of several key components that work together to ensure efficient compost turning operations. The specific components are as follows:

1.Frame

The frame is the basic supporting component of the twin-screw compost turner. It is welded from high-strength steel and possesses sufficient strength and rigidity to withstand the weight of the equipment and the loads generated during operation. The frame houses the spiral compost turning mechanism, travel mechanism, power system, and electronic control system.

2.Spiral compost turning mechanism

The core working component of the twin-screw compost turner consists of two screw shafts, screw blades, and a transmission mechanism. The screw shafts are made of high-strength alloy steel, offering excellent wear resistance and bending resistance. The screw blades are distributed in a continuous spiral pattern on the shafts and are made of wear-resistant steel plates with a special surface treatment for improved wear resistance. The transmission mechanism, consisting of a motor, a reducer, and a coupling, provides power to the screw shafts, enabling them to rotate at a constant speed (typically 30-60 rpm).

3.Traveling mechanism

The machine consists of a drive motor, a speed reducer, and wheels (or tracks) to propel the equipment within the fermentation site or tank. The travel mechanism enables forward, reverse, and steering movement. The travel speed can be adjusted to suit the fermentation process, typically between 0.3 and 2 meters per minute. The wheels (or tracks) are made of wear-resistant material to adapt to varying terrain conditions.

4.Powertrain

The system consists of an auger drive motor and a travel drive motor. The auger drive motor powers the auger turning mechanism, with power ranging from 15-55kW depending on the machine model. The travel drive motor powers the travel mechanism, with power generally ranging from 5.5-15kW. The power system utilizes variable frequency control, allowing for speed adjustments based on material characteristics and operational requirements, improving the machine's energy efficiency and adaptability.

5.Electronic control system

The system consists of a control cabinet, an operating console, sensors, and actuators. The operator controls the machine's movement and screw shaft rotation through the console. Sensors monitor the machine's operating status (such as motor current and screw shaft speed) and parameters such as the temperature and humidity of the fermentation material in real time. If any of these parameters are abnormal, the system automatically issues an alarm and shuts down the machine, ensuring safe and stable operation.

6.Adjustment device

It includes a screw shaft height adjustment device and a spacing adjustment device. The screw shaft height adjustment device can adjust the height of the screw shaft according to the pile height of the material to ensure that the spiral blades can fully contact the material; the spacing adjustment device can adjust the distance between the two screw shafts according to the characteristics of the material and fermentation requirements, improving the turning effect and material uniformity.

How does a double-screw compost turning machine compost organic fertilizer raw materials?

The process of composting organic fertilizer raw materials with a double-screw compost turning machine is a systematic biological fermentation process, which requires strict control of each link. The specific steps are as follows:

1.Raw material pretreatment

The collected organic fertilizer raw materials are crushed and screened to remove impurities (such as rocks and plastic). The particle size is controlled within a certain range (generally 2-8 cm) to facilitate fermentation. The carbon-nitrogen ratio and moisture content are also adjusted based on the raw material's characteristics. The carbon-nitrogen ratio is generally controlled at 25-30:1, and the moisture content is controlled at 50%-60%. If the moisture content is too high, dry materials such as straw and sawdust can be added to adjust the moisture content. If the moisture content is too low, water can be added as needed.

2.Raw material accumulation

The pre-treated raw materials are stacked into strips at the fermentation site or placed in fermentation tanks. The width of the strips (or fermentation tanks) is generally 3-6 meters, and the height is 1-2 meters. The length depends on the site and production volume. During the stacking process, equipment such as loaders or conveyors can be used to assist in the operation to ensure the raw materials are evenly stacked.

3.Turning and fermentation

Start the twin-screw compost turner and adjust the height and spacing of the screw shafts to suit the material's stacking state. The machine moves along the length of the windrow (or fermentation tank), and the screw shaft rotates. The spiral blades lift the material from the bottom and toss it to the sides, ensuring thorough mixing and ventilation.

During the fermentation process, the frequency of turning the compost should be determined based on the temperature of the material. Generally, the first turning is performed when the material temperature reaches 60-70°C. Thereafter, turning is performed every 1-2 days. The specific turning frequency can be adjusted based on the fermentation progress. The entire fermentation cycle generally lasts 12-25 days.

4.Maturity judgment

When the material temperature gradually drops to near ambient temperature and the material becomes dark brown, loose, has an earthy smell, and no noticeable odor, it is considered mature. At this point, the mature material can be removed from the fermentation site or fermentation tank for subsequent processing (such as crushing, screening, granulation, etc.).

| Model | Main Motor | Small Car Moving Motor | Big Car Moving Motor | Hydraulic Pump Motor |

| SLP-10m | 15KW | 1.5KWX2 | 1.5KWX2(4) | 4KW |

| SLP-12m | ||||

| SLP-15m | ||||

| SLP-20m |