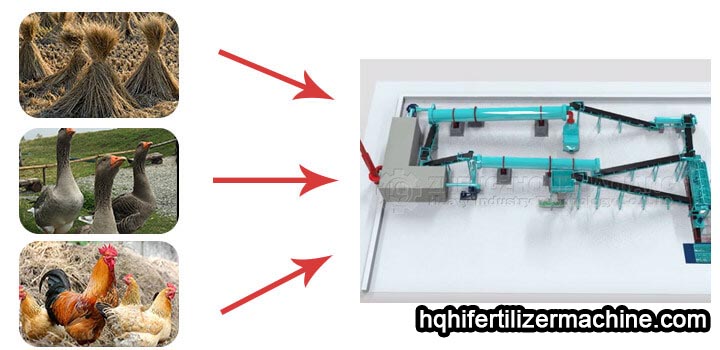

Organic fertilizer production is a complicated project. Generally, the design of organic fertilizer production lines is designed according to two production principles, one is the principle of organic fertilizer fermentation, and the other is the principle of organic fertilizer granulation. The classification of organic fertilizer production line includes powdered organic fertilizer production line and granular organic fertilizer production line. The granular organic fertilizer production line is based on the powdered organic fertilizer production line to add granulator, dryer, cooler and other equipment. Below we will focus on the process flow of the granular organic fertilizer production line.

The

organic fertilizer production line also has the advanced degree of equipment. The advanced organic fertilizer production line has the advantages of labor saving, energy saving, small area occupation, low fertilizer cost, and no pollution to the environment.

The granulation principle of the organic fertilizer production line is mainly to reproduce the fermented powdered organic fertilizer into granules. This process requires more equipment, generally including a mixer-a grinder-a granulator-a dryer-cooling machine-screening machine-film machine-packaging machine and so on.

Process flow of organic fertilizer production line

1. The recovered livestock and poultry manure directly enters the fermentation area. After one fermentation and two aging stacks, the odor of livestock and poultry manure is eliminated. At this stage, fermentation strains can be added to decompose the crude fiber, so that the particle size requirements after crushing meet the particle size requirements of the fertilizer granulator.

2. Pulverize the fermented material after completing the second aging and stacking process, and enter the mixing mixer. Before mixing and mixing, according to the recipe, add N, P, K and some other trace elements to the mixing mixer to start mixing.

3. Transfer the mixed materials to the granulator, granules pass through the dryer and enter the cooling machine, the materials will be sieved after reaching room temperature, and the particles that meet the requirements will enter the coating machine to wrap the coating film and start packaging. After being crushed by the crusher, the granules are returned to the granulation system and continue to granulate.

4. Finished products are automatically packaged.