Pig manure organic fertilizer has complete nutrition and long-term fertilizer effect. Pig manure

organic fertilizer production not only contains amino acids, protein, sugar and other organic nutrients, but also contains n, P, K, medium elements (CA, Mg, s, etc.) and trace elements (Fe, Mn, Cu, Zn, etc.) that are beneficial to crop growth. On the premise of increasing the organic matter, nitrogen, phosphorus, potassium, calcium, magnesium and various trace elements in the soil, compared with chemical fertilizer, organic fertilizer is slowly humic decomposition in the soil, and the fertilizer effect is more lasting.

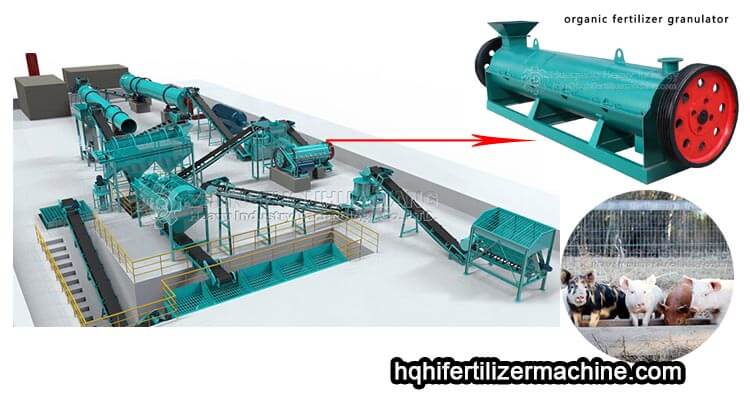

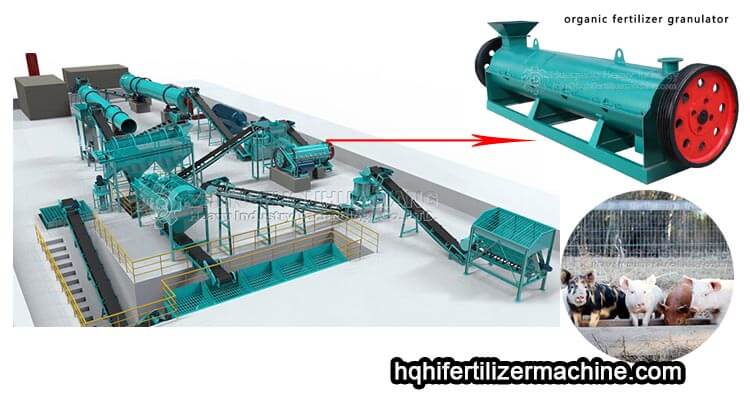

In the pig manure

organic fertilizer production line, there are two steps to process commercial organic fertilizer: the early fermentation and treatment part and the deep processing granulation part. Pig manure organic fertilizer granule production line is mainly equipped with the following equipment: tipper, crusher, batching machine, mixer, granulator, dryer, cooler, screening machine, coating machine, automatic packer. The general production steps are as follows: raw material fermentation, raw material mixing, raw material granulation, particle drying, particle cooling, particle grading, finished product coating and finished product packaging.

The process flow of pig manure organic fertilizer production line is as follows:

① Raw material fermentation - ② automatic batching system with scale - ③ crushing and mixing - ④ disc granulation,

drum granulation, extrusion granulation - ⑤ dryer drying of organic fertilizer particles - ⑥ cooling machine cooling of organic fertilizer particles - ⑦ Screening machine Screening qualified organic fertilizer particles - ⑧ Coating machine coating particles, smoother - ⑨ Automatic filling of organic fertilizer particles by packaging scale - ⑩ Sealing.