The principle of

drum granulation is that the material depends on the surface tension, appropriate liquid phase, extrusion pressure generated by rolling between materials, and the correct movement direction of the material in the granulator is centered on small particles, which are bonded into balls in rolling.

The drum granulation

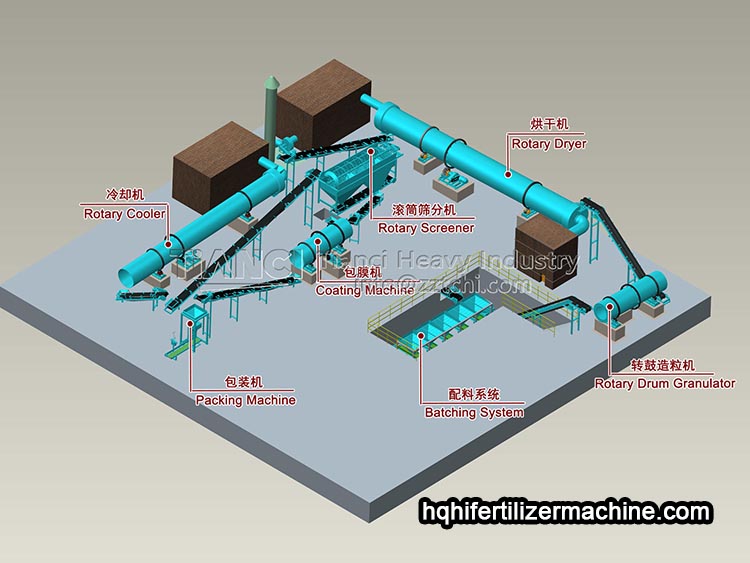

fertilizer production line mainly includes equipment: crusher, mixer, belt conveyor, drum granulator, dryer, cooler, screening machine, coating machine, packaging machine.

Equipment flow of drum granulation fertilizer production line

- 1.Raw material ingredients: urea, ammonium nitrate, ammonium chloride, ammonium sulfate, ammonium phosphate (monoammonium phosphate, diammonium phosphate, bicalcium, procalcium), potassium chloride (potassium sulfate) and other raw materials are provided in a certain proportion (according to the market demand and soil testing results of various regions).

- 2.Raw material mixing: mix the prepared raw materials evenly to improve the overall uniform fertilizer efficiency content of the fertilizer particles.

- 3.Granulation of raw materials: feed the evenly stirred raw materials to the drum granulator for granulation.

- 4.Particle drying: send the particles made by the granulator to the dryer, dry the moisture contained in the particles, increase the particle strength, and facilitate the storage.

- 5.Particle cooling: the temperature of dried fertilizer particles is too high, which is easy to agglomerate. After cooling, it is convenient for bagging, storage and transportation.

- 6.Particle screening: the particles after cooling are sieved, and the unqualified particles are crushed and re-granulated, and the qualified products are screened out.

- 7.Finished costing: the qualified products are coated to increase the brightness and roundness of the particles.

- 8.Packaging of finished products: put the coated particles, i.e. finished products in bags, in a ventilated place for preservation.