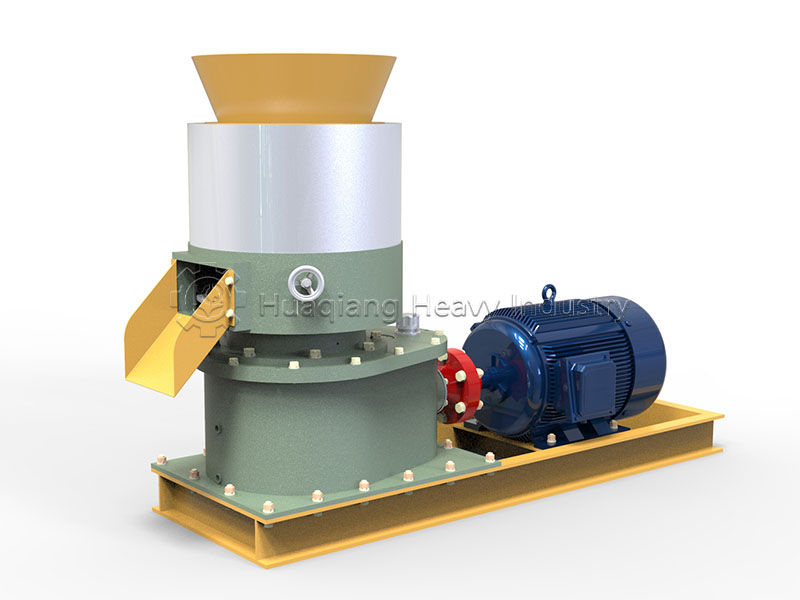

When a flat die granulator is in operation, material first enters the feed inlet and is evenly conveyed to the pulverizing unit, where it is fully pulverized to meet subsequent processing requirements. The pulverized material is then transported by a screw conveyor to the pressing area. In the pressing area, the pressing rollers work closely with the flat die, forcing the material through the die holes under strong pressure, initially forming pellets. Next, the pellets are cut into the desired length by a cutter and leave the pressing area. The hot pellets then enter the cooling unit, where they are rapidly cooled by air or water, stabilizing their shape and properties. Finally, the cooled pellets are screened and packaged before being released to the market as finished products.

The flat die granulator's pressing rollers feature wide grooves, ensuring pressure resistance and wear resistance. The larger rollers can withstand greater pressure, while the wider grooves effectively prevent material accumulation and ensure smooth material flow into the pressing area. The evenly distributed design of multiple pressing rollers ensures smoother operation while increasing the pressing area, significantly improving production efficiency. Taking biomass pellet production as an example, this design can increase yields by 30%-50%, effectively reducing production costs.

The flat die granulator achieves efficient material forming through its ingenious structural design and scientific workflow. Currently, this principle is widely used in feed, biomass energy, fertilizer, and other fields. With continued technological advancement, it is expected to play a significant role in even more areas in the future, bringing greater convenience and benefits to industrial production and resource utilization.