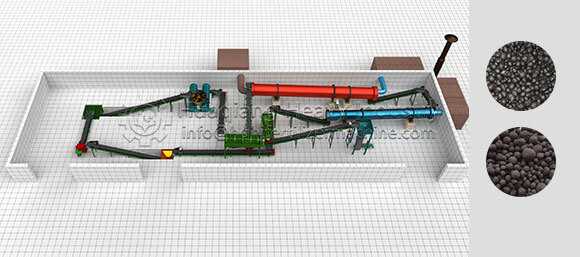

An organic fertilizer production line is the core solution for turning agricultural and livestock waste into valuable resources. Through scientific processing, various organic wastes are converted into high-efficiency organic fertilizers, enabling a circular economy and reducing environmental pollution.

1.Agricultural Waste

Crop straw, rice husks, peanut shells, corn cobs, and similar waste are rich in cellulose and organic matter. The production line uses processes like crushing and fermentation to convert them into organic fertilizer rich in humus.

2.Livestock Manure

Manure from chickens, pigs, cattle, etc., contains high levels of nitrogen, phosphorus, potassium, and organic matter. The organic fertilizer production line uses high-temperature fermentation, odor removal, and sterilization to turn it into safe and highly effective bio-organic fertilizer.

3.Food Waste

Leftovers, fruit peels, vegetable scraps, and other kitchen waste have high organic content and easily decompose and smell. Using aerobic fermentation technology, the production line converts them into nutrient-rich organic fertilizer.

4.Food Processing Byproducts

Distiller's grains, bean dregs, fruit pomace, sugar residue, and other industrial food processing leftovers contain abundant organic nutrients. The production line mixes these with straw or manure for fermentation to produce high-value-added organic fertilizer.

5.Garden Waste

Dead branches, fallen leaves, lawn clippings, and other green waste can be crushed and composted by the production line to make organic fertilizer for urban greening or home gardening.

The organic fertilizer production line is key technology for waste resource utilization. It transforms organic waste from agriculture, livestock, food processing, urban living, and other sectors into high-value fertilizer, supporting the growth of the circular economy.