In the sheep manure organic fertilizer industry, accurately determining a organic fertilizer production line’s capacity is critical. Here are the key factors that define its output:

Equipment and Production Process

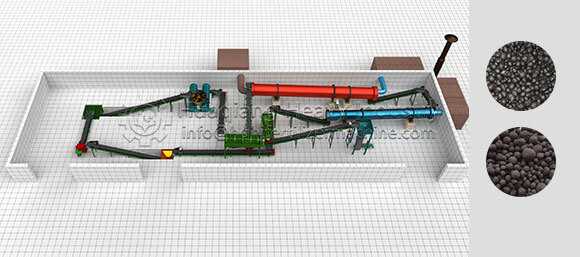

1.Equipment Selection: The choice and combination of machinery (fermentation systems, crushers,fertilizer granulators, sieving equipment, etc.) directly impact capacity.

2.Production Process: Automated, streamlined processes (such as continuous fermentation or advanced control systems) boost efficiency and output.

Raw Material Supply and Handling

1. Material Availability: Stable sheep manure supply is essential. Insufficient raw materials limit production capacity.

2.Processing Capability: Equipment handling limits (such as fermentation speed, crushing efficiency) determine how much raw material can be processed daily.

Production Environment and Management

1. Environmental Conditions: Temperature, humidity, and ventilation affect fermentation speed and overall efficiency.

2.Operational Management: Skilled staff, proper maintenance schedules, and organized workflows maximize uptime and productivity.

Other Considerations

1. Equipment Maintenance: Quick repairs and preventive upkeep minimize downtime.

2. Market Demand: Sales volume and market needs influence whether to scale up or adjust production.

In short, a sheep manure organic fertilizer production line’s capacity depends on balancing raw material supply, equipment performance, process efficiency, and operational practices. A thorough evaluation of these factors ensures a cost-effective, high-output system tailored to your needs.