For livestock farms, picking the right organic fertilizer production line is a big deal. It’s not just about handling farm waste properly – it also affects how efficiently you can produce quality fertilizer. Here’s what really matters when making your choice:

1. Farm Size Matters

Smaller operations with limited manure output should go for compact, easy-to-use systems. Think basic fermentation equipment paired with simple crushing and mixing tools. These setups keep costs low while getting the job done.

Mid-sized farms need more complete solutions. Look for mid-capacity fermentation tanks with proper ventilation and climate control. Add decent crusher and fertilizer granulators to maintain both quality and output.

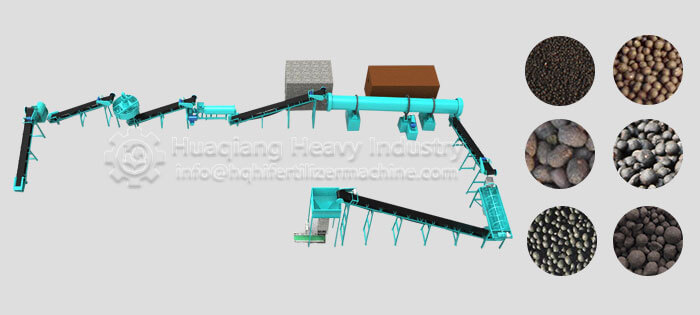

Big commercial farms require heavy-duty automated systems. We’re talking continuous large-scale fermentation setups with conveyor belts, processing units, and packaging systems that can handle massive manure volumes and pump out fertilizer fast for market sales.

2. Production Target

If you’re mainly making fertilizer for your own crops, focus on budget-friendly basics. Reliable fermentation gear and simple processing equipment will do the trick. No need for extras.

But if you’re selling commercially, quality and efficiency become non-negotiable. You’ll want precision ingredient mixers and advanced granulation tech to meet national standards and keep up with market demands.

3. Funding Budget

When the financial budget is limited, farms can choose to build the organic fertilizer production line in phases. Start with essential fermentation gear, then add processing equipment later as funds allow. It’s about covering basic needs first while leaving room to upgrade down the line.

If you have sufficient funds, you can choose a fully automated production line. These top-tier systems deliver better tech, higher quality, and faster production – worth the upfront cost for long-term efficiency and stable output.