Fertilizer crushers are core auxiliary equipment in organic and chemical fertilizer processing. The selection directly impacts crushing efficiency, production capacity, and subsequent processing quality. The key to selection is following the principle of "matching needs and ensuring practicality."

First, consider the crushing requirements and material characteristics. Different fertilizers have varying hardness and moisture content. For processing caked organic fertilizers and medium-hard granular fertilizers, conventional models are suitable; for crushing hard mineral fertilizers and large lumps of fertilizer, models with strong crushing power and wear resistance are needed. Simultaneously, consider the required particle size after crushing to determine the equipment precision and ensure it meets subsequent needs.

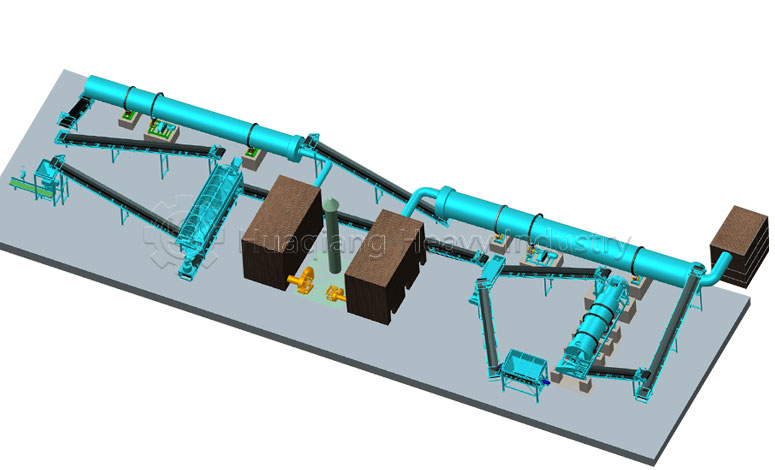

Secondly, focus on equipment performance and suitability for the application. For small-scale processing or home use, prioritize small, easy-to-operate, and low-energy-consumption models; for large-scale production requiring integration with organic fertilizer production lines or NPK fertilizer production lines, choose models that can be linked, have matching capacity, and are easy to maintain to ensure a smooth process.

Finally, avoid selection pitfalls and consider practicality. Do not blindly pursue high capacity to avoid waste; pay attention to the durability of wear parts and choose models with easily removable and replaceable parts to reduce subsequent maintenance costs.

In summary, choosing a fertilizer crusher requires matching material characteristics, production scale, and subsequent needs, while considering performance and practicality, to achieve efficient crushing, reduce costs, and suit various processing scenarios.