Bio-organic fertilizer production lines need to balance flexibility, scalability, and cost-effectiveness to meet the needs of businesses of all sizes. Whether it’s a small farm making fertilizer for its own use or a large industrial operation running continuous processing, a well-designed setup ensures efficient and steady output.

1.Small-Scale Production Lines

Perfect for family farms, small co-ops, or organic growing bases. Features include:

Simple equipment: Uses trough composting or windrow piles, paired with small crushers, mixers, and screens.

Low investment: Manual turning with basic compost turning machines keeps startup costs down.

Flexible adjustments: Formulas can be tweaked based on materials (like livestock manure, straw, or mushroom residue) for small-batch production.

2.Medium-Scale Production Lines

Suited for fertilizer processing plants or mid-sized farms. Core setup includes:

Turning equipment: Trough turners or crawler compost turners to speed up fermentation.

Crushing and mixing: Chain crushers + double axis mixers for even blending.

Optional granulation: Disc or flat die granulators for powdered or pelletized fertilizer.

Automated control: Temperature and humidity sensors + PLC systems to optimize fermentation.

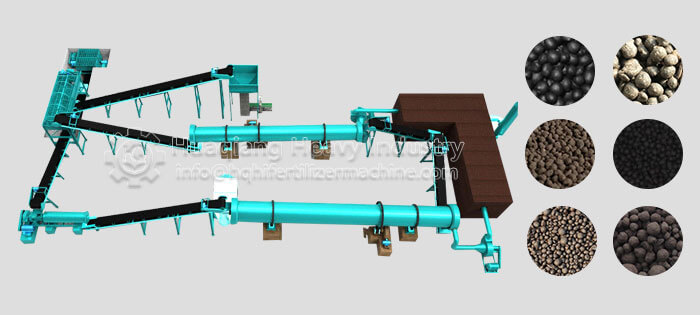

3.Large-Scale Production Lines

Built for professional fertilizer manufacturers. Features include:

High-efficiency fermentation: Smart fermentation tanks or continuous turning systems cut down the composting cycle.

Smart ingredient dosing: Automated weighing and mixing systems for precise NPK and microbial inoculant blending.

Versatile granulation: Drum or extrusion granulators to suit different market needs.

Automated packaging: Weighing, sealing, and palletizing done by machine to reduce labor costs.

Bio-organic fertilizer production line designs should match equipment combinations to the production scale, material types, and budget—ensuring efficient, low-cost, and sustainable operations.