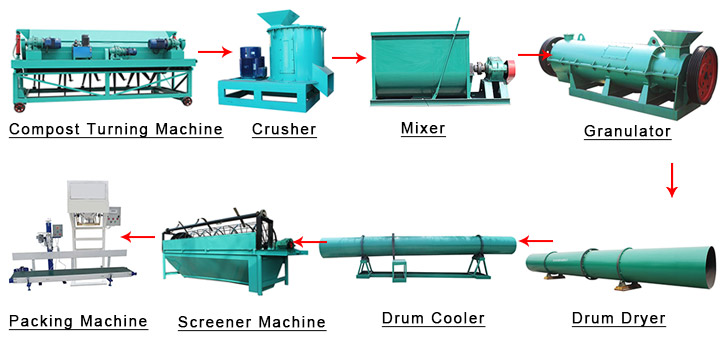

The production process of cow manure organic fertilizer is generally after fermentation of raw materials, it can be directly processed and granulated. The whole set of

fertilizer equipment needs to be equipped with fermentation compost turner machine, semi wet material crusher, roller screen, horizontal mixer, granulator, dryer, cooler, roller screen, coating machine, automatic quantitative packaging machine and other equipment for deep processing and granulation.

Production process of cow manure organic fertilizer

1. Fermentation process

The purpose of cow dung fermentation is to reduce the volatile matter and odor in the waste, kill the parasite eggs and pathogenic microorganisms, and achieve the purpose of harmless.

First of all, the cow manure should be dried or drained to keep its water content below 85%. Then, the straw powder should be added with a ratio of 7:3 to control the carbon ratio of raw materials (cow manure) and auxiliary materials (straw powder) at 23-28 and the water content at 52% - 68%. Finally, the organic fertilizer fermentation agent was added.

It can also build a fermentation tank with a length of 50 meters and a width of 4 meters. The mixture is stacked in the fermentation tank, and then turned over by the organic fertilizer turning machine. The turning depth can reach 0.7m ~ 1m. Through the fertilizer equipment, the compost is turned evenly and thoroughly, and the low-level raw materials are turned into the middle and upper part of the compost, so as to fully mature. After the first turning, the pile should be turned every day. However, when the temperature is over 70 ℃, the pile must be turned over immediately, otherwise the beneficial microorganisms and fermentation bacteria will be killed in large quantities, which is not conducive to fermentation and maturity.

2. Crushing process

The fermented cow dung is put into the silo, and then the animal dung is transferred to the fertilizer grinder by the belt, which is used for crushing and stirring, so as to facilitate the preparation of granulation.

3. Granulation process

In the

organic fertilizer production line, the output of organic fertilizer determines which kind of organic fertilizer production equipment is selected, such as the most important pelletizing equipment. Its size determines the shape and output of fertilizer pelletizing.

It is suggested that the standard of fermentation and maturity of cow dung

1. According to the color, the color of general fertilizer will change to brown or dark brown, and the content of ammonium nitrogen will increase significantly.

2. Look at the lixivium, mix the decomposed organic fertilizer with clear water (1:5), and place it for 5 minutes.

3. In terms of volume, the volume of compost is 1 / 3-1 / 2 larger than that of newly stacked piles. Finally, spread the fermented organic fertilizer evenly on the drying ground, with a thickness of no more than 20cm, and often turn it over to make the water content less than 32%.